2025-05-26

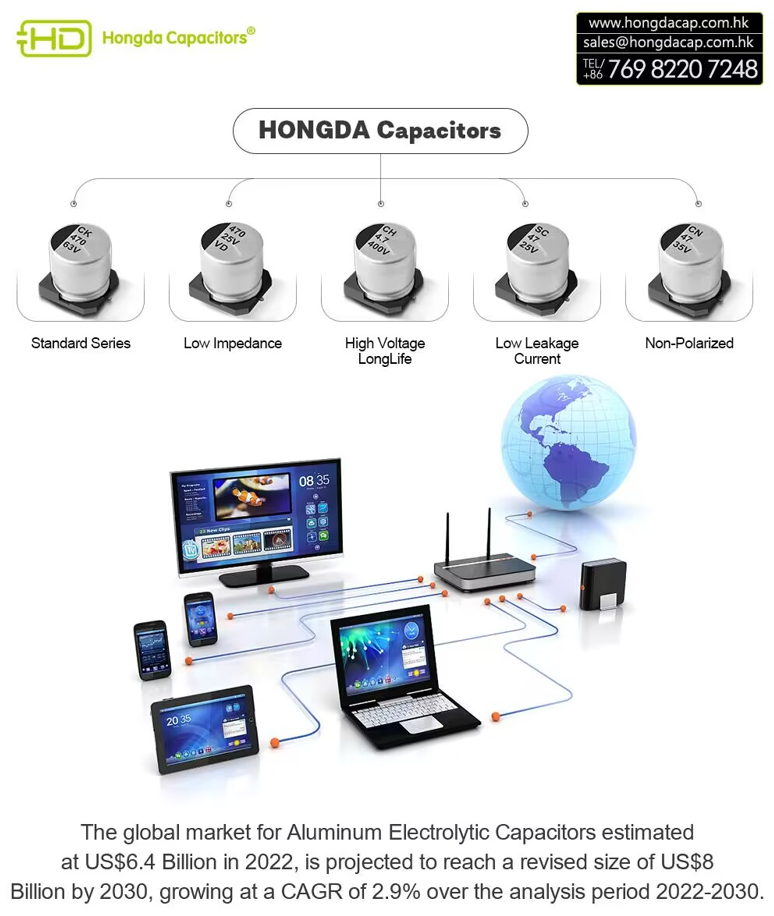

In the realm of electronic components, electrolytic capacitors play a crucial role in various circuits, providing energy storage and filtering functions. Among them, radial electrolytic capacitors and surface - mount device (SMD) electrolytic capacitors are two commonly used types. Although they share the same basic working principle of electrolytic capacitors, there are significant differences between them in several aspects.

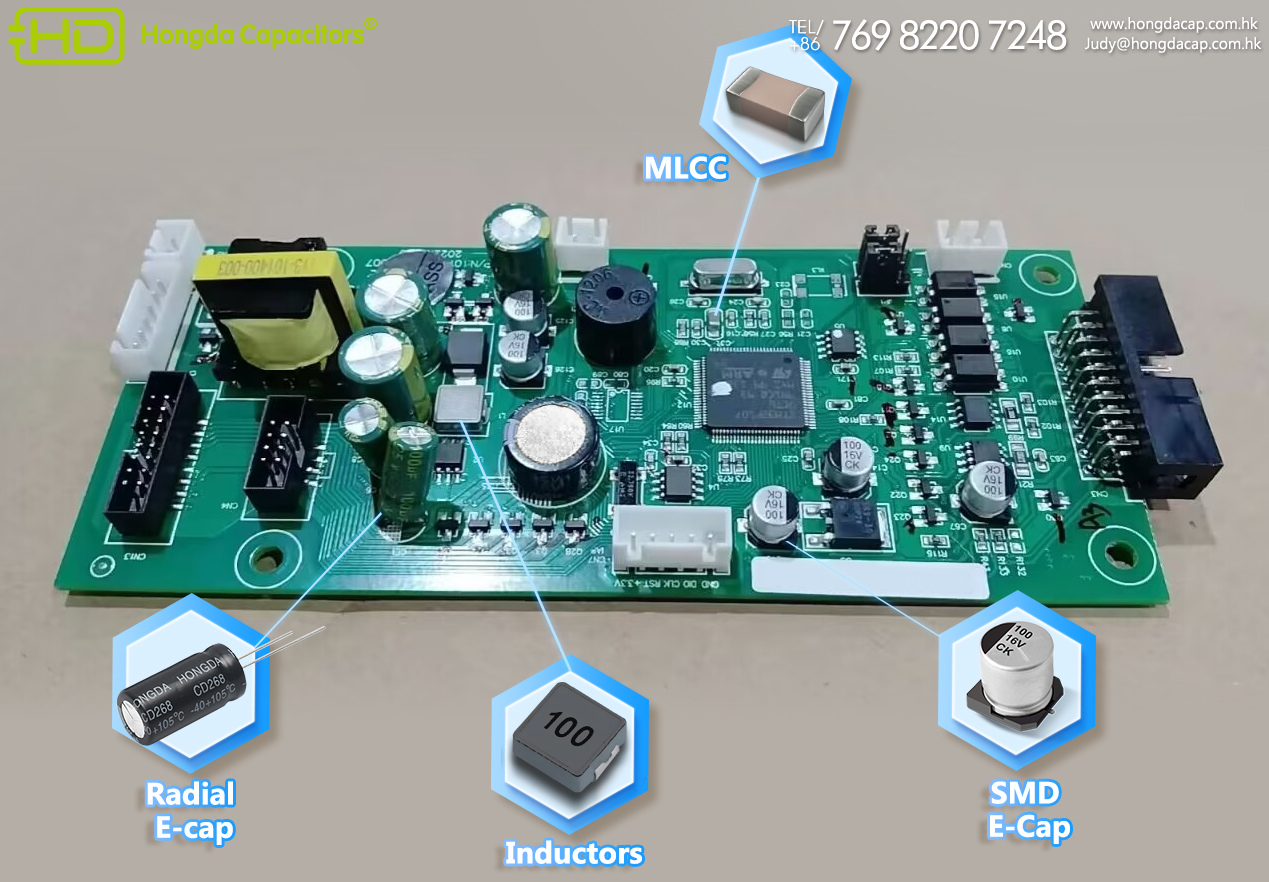

Radial Electrolytic Capacitors

Radial electrolytic capacitors are typically cylindrical in shape. They feature two leads that extend from one end of the capacitor body in a radial direction, which gives them their name. These leads are usually made of metal and are designed for insertion into holes on a printed circuit board (PCB). The size of radial electrolytic capacitors can vary widely, with larger ones often being able to handle higher voltage and capacitance values. The body of the capacitor is usually encased in a plastic or rubber sleeve, which provides mechanical protection and also serves as an insulator.

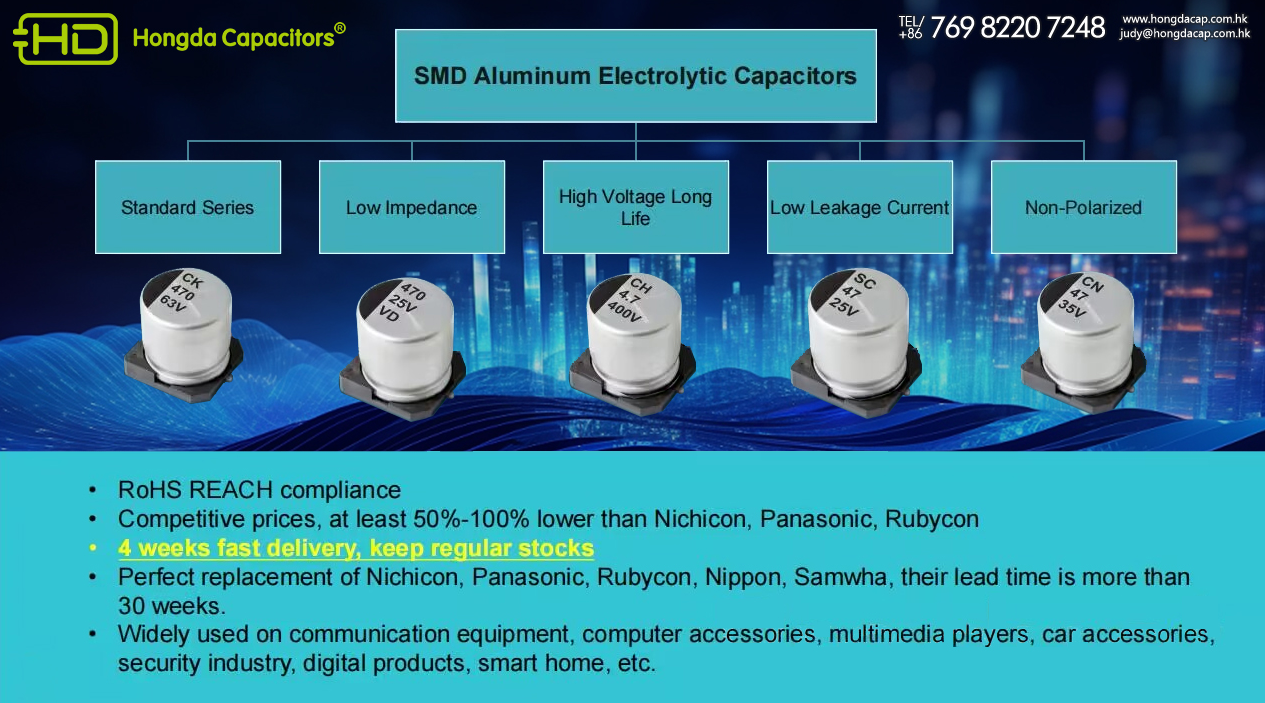

SMD Electrolytic Capacitors

SMD electrolytic capacitors, on the other hand, have a flat and rectangular shape. Instead of leads, they have metal pads on their bottom surface. These pads are designed to be soldered directly onto the surface of a PCB using surface - mount technology. SMD electrolytic capacitors are much smaller in size compared to their radial counterparts. This compact form factor makes them highly suitable for modern, space - constrained electronic devices where minimizing the footprint of components is crucial. The smaller size also allows for higher component density on the PCB, enabling more complex circuit designs.

Installation and Assembly

Installation of Radial Electrolytic Capacitors

Installing radial electrolytic capacitors requires through - hole technology. First, holes are drilled on the PCB according to the lead pitch of the capacitor. Then, the capacitor's leads are inserted through these holes from the top side of the PCB, and the leads are soldered on the bottom side. This process is relatively straightforward but can be more time - consuming, especially for mass production, as it often requires manual insertion or the use of automated insertion machines that are less efficient than surface - mount assembly equipment. Moreover, the through - hole installation method occupies more space on both sides of the PCB, which may limit the overall design flexibility.

Installation of SMD Electrolytic Capacitors

SMD electrolytic capacitors are installed using surface - mount technology. Solder paste is first applied to the pads on the PCB using a stencil. Then, the capacitors are placed on the pads using a pick - and - place machine with high precision. Finally, the PCB is passed through a reflow oven, where the solder paste melts and forms a strong electrical and mechanical connection between the capacitor pads and the PCB pads. This surface - mount assembly process is highly automated, allowing for high - speed and high - volume production. It also offers better precision and consistency in component placement, and since it only occupies space on one side of the PCB, it provides more flexibility in circuit layout design.

Electrical Performance

Capacitance and Voltage Ratings

Both radial and SMD electrolytic capacitors are available in a wide range of capacitance and voltage ratings. However, generally, radial electrolytic capacitors can be manufactured with larger capacitance and higher voltage ratings more easily. This is because their larger physical size allows for the use of more dielectric material and a larger electrode area, which are essential for achieving high capacitance and voltage - handling capabilities. For example, in some power supply applications that require very high - capacitance values (in the thousands of microfarads) and relatively high operating voltages (such as 400V or more), radial electrolytic capacitors are often the preferred choice.

SMD electrolytic capacitors, due to their smaller size, usually have more limited capacitance and voltage ratings. They are more commonly used in applications where moderate capacitance values (up to a few hundred microfarads) and lower to moderate voltage levels (e.g., up to 100V) are sufficient, such as in signal processing circuits, small - scale power management circuits of portable devices, and consumer electronics.

Equivalent Series Resistance (ESR) and Equivalent Series Inductance (ESL)

ESR and ESL are important parameters that affect the performance of electrolytic capacitors in AC circuits. Radial electrolytic capacitors typically have higher ESR and ESL values compared to SMD electrolytic capacitors. The longer leads of radial capacitors contribute to higher inductance, and the internal construction and larger size can result in higher resistance. Higher ESR can cause more power dissipation in the form of heat when the capacitor is used in high - frequency AC circuits, reducing its efficiency. Higher ESL can also limit the high - frequency performance of the capacitor, causing signal distortion and attenuation.

SMD electrolytic capacitors, with their shorter electrical paths and more compact structure, generally have lower ESR and ESL. This makes them more suitable for high - frequency applications, such as in high - speed digital circuits, RF circuits, and switching power supplies where low ESR and ESL are required to minimize power losses and ensure signal integrity.

Cost and Application Scenarios

Cost

The cost of radial and SMD electrolytic capacitors can vary depending on several factors, including size, capacitance, voltage rating, and production volume. In general, radial electrolytic capacitors may be relatively cheaper in terms of the component cost itself, especially for larger, standard - size capacitors with common ratings. However, when considering the overall cost of the assembly process, including the cost of PCB design, manufacturing, and installation, SMD electrolytic capacitors can be more cost - effective in high - volume production. This is because the automated surface - mount assembly process is more efficient and requires less labor compared to the through - hole assembly of radial capacitors.

Application Scenarios

Radial electrolytic capacitors are often used in applications where high capacitance and high voltage are required, such as in power supplies for desktop computers, large - scale industrial equipment, and audio amplifiers. Their larger size and higher power - handling capabilities make them suitable for these applications where space is less of a constraint.

SMD electrolytic capacitors, due to their small size, low ESR/ESL, and suitability for automated assembly, are widely used in modern consumer electronics, such as smartphones, tablets, laptops, and digital cameras. They are also commonly found in portable electronic devices, automotive electronics, and high - frequency circuit boards where space - saving, high - frequency performance, and high - density component placement are essential requirements.

In conclusion, radial electrolytic capacitors and SMD electrolytic capacitors each have their own characteristics and advantages. The choice between them depends on various factors such as the specific requirements of the electronic circuit, available space on the PCB, operating frequency, power - handling needs, and cost - effectiveness considerations. Understanding these differences is crucial for engineers and designers to make the right selection of electrolytic capacitors in different electronic applications, ensuring optimal performance and reliability of the final products.

Hongda Capacitors can offer both of the Radial Electrolytic Capacitors & SMD Electrolytic Capacitors, pls check via Email: judy@hongdacap.com.hk

Whatsapp&WeChat: +86 136 6989 7281