2025-08-30

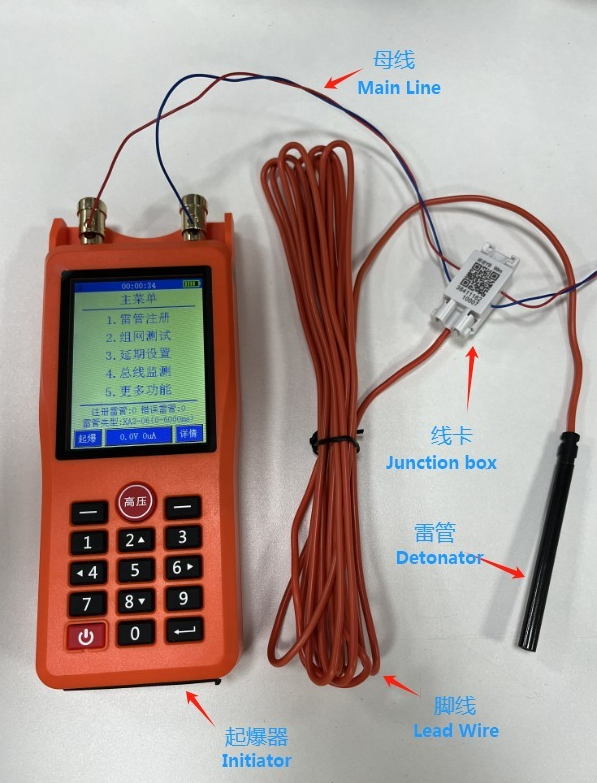

Electronic detonators have become the backbone of modern blasting operations—from mining and construction to infrastructure development—thanks to their unmatched precision, safety, and controllability. Unlike traditional pyrotechnic detonators, these advanced systems rely on digital technology to regulate detonation timing, eliminating risks of accidental initiation and optimizing blast efficiency. At the center of every high-performance electronic detonator lies a set of critical components, and Hongda Capacitor stands as a leading supplier, delivering four essential elements: capacitors, control modules, bridge wires, and junction boxes with a complete set of wires (junction boxes + wires). This article explores how Hongda’s tailored components address the unique demands of electronic detonators, ensuring consistency, durability, and safety across diverse industrial applications.

Electronic detonators have redefined blasting by replacing chemical delay mechanisms with digital control. This shift offers three key advantages:

Microsecond-level timing accuracy: Enables engineers to design blasts that fragment rock or materials uniformly, reducing waste and improving post-blast cleanup efficiency.

Enhanced safety: Encrypted digital signals prevent accidental activation from stray currents, radio interference, or environmental factors—critical for high-risk sites like underground mines or urban construction zones.

Remote operability: Supports wireless or wired control, allowing operators to trigger blasts from safe distances and monitor performance in real time.

For these benefits to hold, every component in the detonator must perform flawlessly—even in harsh conditions (extreme temperatures, humidity, dust, or mechanical shock). Hongda Capacitor’s components are engineered to meet these rigorous standards, acting as the “building blocks” of reliable electronic detonator systems.

Each of Hongda’s four key offerings serves a distinct, irreplaceable function in electronic detonators. Together, they form a synchronized system that ensures safe, precise detonation every time.

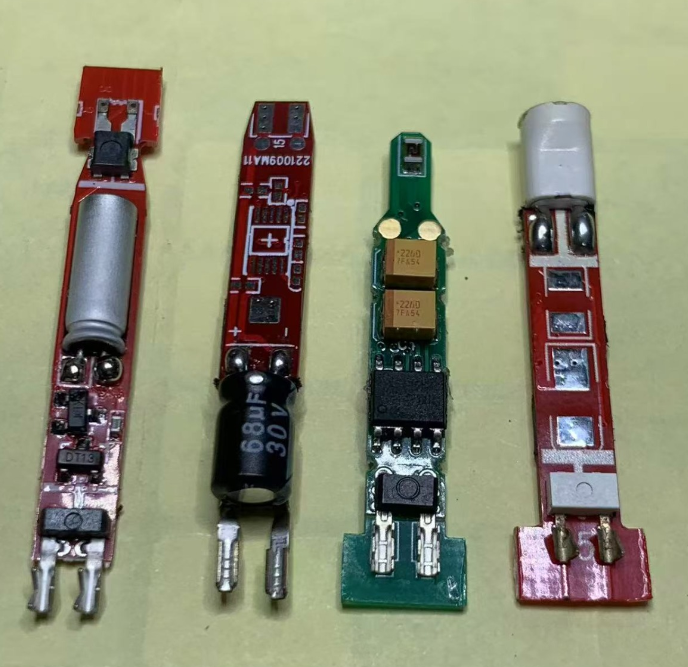

Capacitors: The Energy Storage Backbone

The capacitor is the “power bank” of the electronic detonator, responsible for storing electrical energy and releasing it in a rapid, controlled pulse to ignite the explosive charge. For electronic detonators, not all capacitors are equal—Hongda’s mining- and blasting-grade capacitors are designed with two critical priorities:

High energy density: Delivers enough power to ignite the primary explosive reliably, even in low-temperature environments (-40°C to 60°C) where battery performance degrades.

Low self-discharge: Retains charge for extended periods (up to 6 months of storage) without leakage, preventing misfires caused by insufficient energy.

Hongda’s capacitors use high-quality ceramic or aluminum electrolytic materials, sealed in moisture-resistant casings to withstand dust and humidity. Rigorous testing—including voltage cycling and temperature stress tests—ensures each unit meets IEC 60384 (international standards for capacitors) and industry-specific safety certifications.

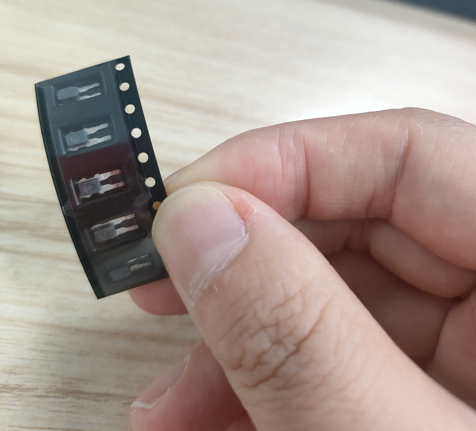

If the capacitor provides power, the control module is the detonator’s command center. This compact, ruggedized unit manages every critical function of the detonator, including:

Timing control: Receives digital signals from the blast controller to set exact detonation times (adjustable in 1ms increments), ensuring synchronization with hundreds or thousands of other detonators in a single blast.

Security encryption: Requires a unique activation code to prevent unauthorized or accidental triggering—blocking interference from radio waves, power lines, or mining equipment.

Fault detection: Monitors internal health (e.g., capacitor charge level, wire continuity) and sends diagnostic data to the blast controller. If a fault is detected (e.g., a damaged wire), the module disables the detonator to avoid misfires or premature blasts.

Hongda’s control modules are built with industrial-grade microchips and encased in IP68-rated housings—making them dustproof and waterproof. Their low power consumption also extends the detonator’s operational life, reducing the need for frequent battery replacements.

The bridge wire is the critical connection between the capacitor’s energy and the explosive charge. When the control module triggers the capacitor, a high-current pulse flows through the bridge wire, causing it to heat rapidly (up to 1,800°C) and ignite the primary explosive (e.g., lead azide or diazodinitrophenol). For reliable ignition, Hongda’s bridge wires meet strict standards:

Uniform resistance: Manufactured from high-purity nickel-chromium (NiCr) alloy with a resistance tolerance of ±1%, ensuring consistent heating across all detonators.

High heat resistance: Withstands repeated thermal cycles without degradation, even in high-humidity environments.

Hongda uses precision drawing and annealing processes to create bridge wires of consistent diameter (as small as 0.02mm), eliminating weak points that could cause ignition failure. Each wire is tested for conductivity and heat resistance before leaving the factory.

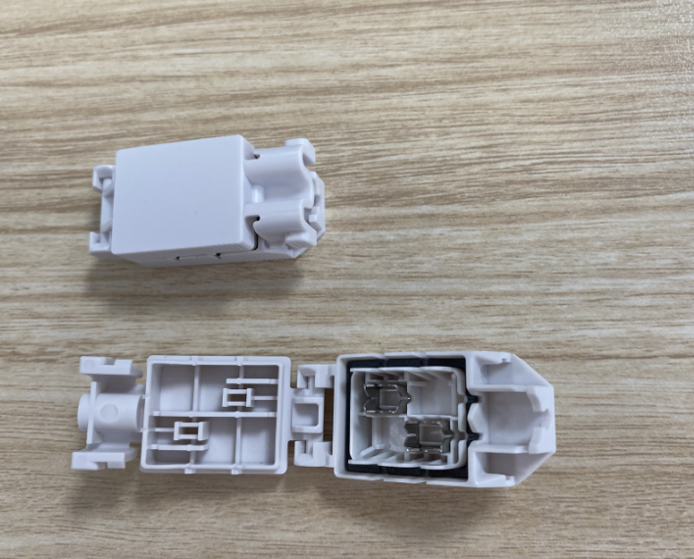

A single blasting operation may require hundreds of electronic detonators, all needing a secure connection to the central blast controller. Hongda’s junction boxes and wires form the “connectivity backbone” of this system:

Junction boxes: Act as distribution hubs, linking multiple detonators (8–32 channels per box) to a single controller line. They include surge protection to shield detonators from voltage spikes caused by heavy machinery or lightning, and modular ports for easy scaling (adding more detonators to a blast pattern).

Wires: Heavy-duty, insulated cables that transmit power and digital signals between the controller, junction boxes, and detonators. Coated in chemical-resistant PVC or polyurethane, they resist abrasion, UV radiation, and corrosion—ideal for surface mining, marine construction, or industrial demolition.

Hongda’s junction boxes are designed for quick installation, with snap-on lids and color-coded ports to prevent wiring errors. The wires feature low signal attenuation, ensuring reliable communication even over long distances (up to 1,000 meters) in large-scale operations like open-pit mines.

As the demand for safer, more efficient blasting grows—driven by trends like automation, sustainability, and deep-underground mining—electronic detonators are evolving. Future systems may integrate AI for blast optimization (reducing energy use and environmental impact) or wireless networks for fully remote operations. Hongda Capacitor is already preparing for these advancements, with ongoing R&D into:

Smaller, higher-energy capacitors to reduce detonator size.

Smart control modules with real-time data analytics.

Self-diagnosing junction boxes that detect wiring faults automatically.

Electronic detonators have transformed industrial blasting by prioritizing precision and safety—and their performance depends entirely on the quality of their core components. Hongda Capacitor’s capacitors, control modules, bridge wires, and junction boxes + wires are engineered to meet the toughest demands of mining, construction, and demolition, delivering reliability that operators can trust. For companies looking to upgrade their blasting operations, Hongda isn’t just a supplier—it’s a partner in building safer, more efficient systems that drive project success.

Whether for a small-scale construction site or a large open-pit mine, Hongda Capacitor’s components ensure that every electronic detonator fires exactly when, where, and how it should—turning blasting from a high-risk task into a controlled, predictable process.

Should you require more information on specific models or technical details, feel free to reach out. The Hongda team is dedicated to providing comprehensive support to ensure a smooth transition. Thanks, and have a nice day!

Email: judy@hongdacap.com.hk

Whatsapp&WeChat: +86 136 6989 7281