2025-11-16

In the intricate world of electronic components, where stability and reliability are paramount, the Surface-Mount Device (SMD) Aluminum Electrolytic Capacitor stands as a fundamental pillar. Characterized by their compact casing and solder terminals for direct PCB mounting, these components are indispensable across a vast spectrum of electronics, from power supplies and industrial controls to consumer appliances. As the industry marches toward greater efficiency and miniaturization, the demand for these reliable capacitors continues to see steady growth.

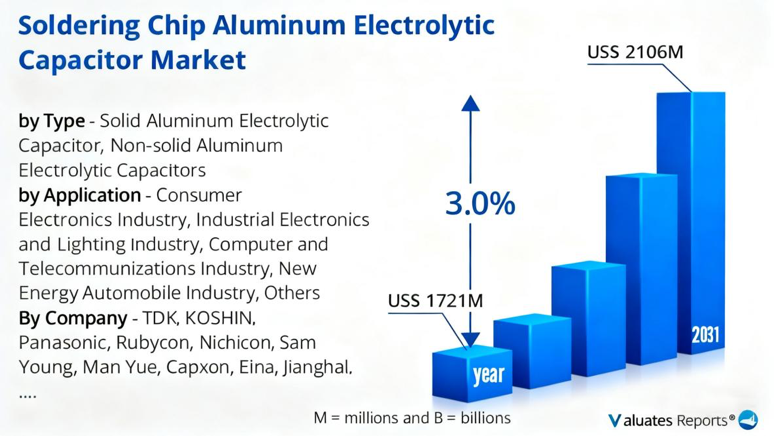

The market landscape reflects this sustained importance. According to a recent industry report, the global Soldering Chip Aluminum Electrolytic Capacitor market was valued at USD 1.721 billion in 2024 and is projected to reach USD 2.106 billion by 2031, growing at a CAGR of 3.0%. This growth is underpinned by their irreplaceable role in providing high capacitance in a robust package. We at Hongda Capacitors are proud to be recognized as one of the key manufacturers in this space, a testament to our rising market presence and commitment to quality.

The global marketplace for chip aluminum electrolytic capacitors is both competitive and crowded, with established players like TDK, Panasonic, Rubycon, and Nichicon holding significant shares. Standing out in such a field requires more than just production capacity; it demands technological consistency, reliable performance, and a deep understanding of application needs. Hongda Capacitors has embraced this challenge, continuously refining our processes to meet the exacting standards of customers worldwide.

SMD Aluminum Electrolytic Capacitors offer numerous advantages over traditional capacitors, such as compact size, high capacitance values, and low equivalent series resistance (ESR). This means they are ideal for applications that require high capacitance in a limited space, helping you optimize the design of your electronic products.

Key Features of Our Chip Aluminum Electrolytic Capacitors:

Hongda Capacitors provides comprehensive electronic component solutions, with a strong reputation for our aluminum capacitors, tantalum capacitors, polymer capacitors, wet tantalum capacitors, and inductors. We are committed to delivering superior quality, maintaining competitive pricing, and ensuring short lead times with readily available stock to provide reliable and efficient support for all our customers' projects. To further assist you, our knowledgeable team of experts is always ready to help select the right capacitors tailored to your specific application requirements.

Designed for Diverse Applications:

Our capacitors are trusted components in:

Future Outlook: Stability as the Key Driver

The steady growth forecast for the chip aluminum electrolytic capacitor market is a clear indicator of its enduring value. As industries like 5G infrastructure, industrial IoT, and renewable energy systems expand, the need for stable, high-capacitance, and cost-effective solutions will only increase.

For Hongda Capacitors, the future strategy is clear: to deepen our commitment to quality and reliability. In an era where system uptime is critical, the consistency of every component is non-negotiable. We are intensifying our focus on rigorous testing, material science, and process control to ensure that every capacitor we ship not only meets but exceeds industry standards.

By strengthening our manufacturing excellence and customer support, Hongda Capacitors is poised to not just participate in this growing market, but to help drive it forward. When engineers worldwide look for a stable, reliable foundation for their power circuits, they can confidently build it with Hongda Capacitors.