2026-01-18

Tantalum capacitors play a critical role in modern electronic systems that require high reliability, stable electrical performance, and compact design. As global electronics continue to evolve toward higher integration and harsher operating environments, tantalum capacitors remain an essential passive component across multiple industries.

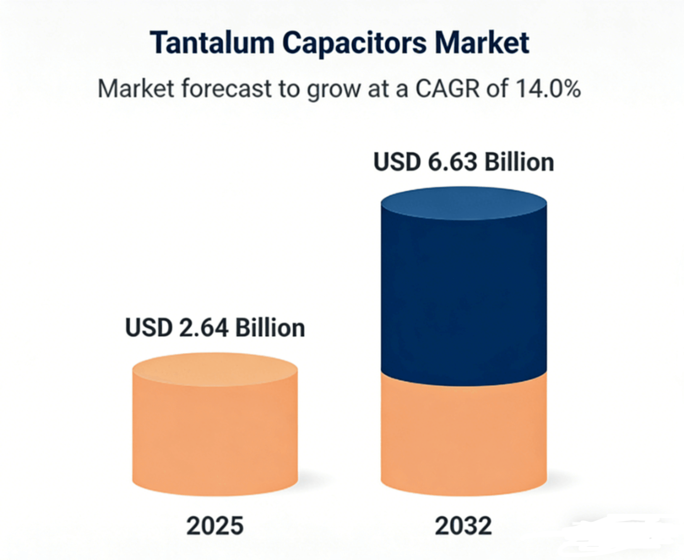

Note: Data in this chart is sourced from public online information, for reference only.

Unlike conventional capacitor technologies, tantalum capacitors are valued for their high volumetric efficiency, excellent frequency stability, and long operational lifespan. These characteristics make them especially suitable for applications where failure is not an option.

In recent years, market demand has shifted steadily toward sectors such as automotive electronics, industrial control systems, aerospace, defense equipment, and power management solutions. These applications typically operate under strict electrical and environmental conditions, driving sustained demand for high-reliability tantalum capacitors.

At the same time, the increasing adoption of advanced electronic modules in electric vehicles, smart energy systems, and industrial automation has further reinforced the importance of stable and efficient capacitor solutions.

Continuous innovation in materials and manufacturing processes has significantly expanded the performance capabilities of tantalum capacitors. High-energy tantalum capacitors enable greater capacitance within limited space, supporting compact circuit design without compromising reliability.

Polymer tantalum capacitors, in particular, have gained strong market acceptance due to their low ESR, improved thermal behavior, and enhanced safety characteristics. These advantages make them well suited for power supply circuits, DC-DC converters, and high-frequency applications where efficiency and stability are critical.

Manufacturers with strong R&D capabilities and advanced production control are best positioned to meet these evolving technical requirements.

The CA55 series polymer tantalum capacitors from Hongda Capacitors are designed for applications requiring low ESR, high ripple current capability, and stable electrical performance.

|

Specification Overview |

|

|

Item |

CA55 Series |

|

Type |

Polymer Tantalum Capacitor |

|

Operating Temperature |

-55°C to +105°C |

|

Capacitance |

0.68µF – 1000µF at 100Hz |

|

Voltage Range |

2.5V – 63V |

|

Leakage Current DCL: |

0.1CV |

Get more details from:

https://www.hongdacapacitors.com/res/Tantalum-Capacitors/ca55-polymer-chip-tantalum-capacitors.pdf

As performance expectations rise, customers increasingly prioritize tantalum capacitor manufacturers with proven production expertise, comprehensive quality systems, and long-term supply stability.

Founded in 1999, Hongda Capacitors is a leading passive component manufacturer specializing in capacitors and inductors. As the leading tantalum capacitors manufacturer in China, Hongda Capacitors holds proprietary patents covering high-energy tantalum capacitors and polymer tantalum capacitors.

The company operates advanced production lines imported from Japan and maintains a complete quality control system, supported by two dedicated chip capacitor R&D centers and an in-house reliability testing laboratory. This vertically integrated manufacturing capability ensures consistent product performance and long-term reliability.

Tantalum capacitors are widely used across industries that demand dependable electrical performance under challenging conditions. In automotive electronics, they support powertrain systems, body control modules, and electronic control units. In aerospace and defense, tantalum capacitors are selected for their proven reliability under extreme temperature, vibration, and voltage conditions.

Industrial equipment, marine systems, and consumer electronics also continue to rely on tantalum capacitors for stable power delivery and signal integrity.

Currently, Our products are widely applied in aircraft, marine systems, consumer electronics, and industrial applications. We have obtained the necessary certificates like ISO9001:2015 and IATF16949.

The global tantalum capacitor market is expected to maintain steady growth, supported by the increasing complexity of electronic systems and rising demand for high-performance, long-life components. While alternative capacitor technologies continue to develop, tantalum capacitors remain irreplaceable in applications where reliability, compact size, and stable electrical behavior are essential.

Manufacturers that combine technological innovation, strict quality control, and application-focused product development will continue to play a key role in shaping the future of the tantalum capacitor industry.